Description

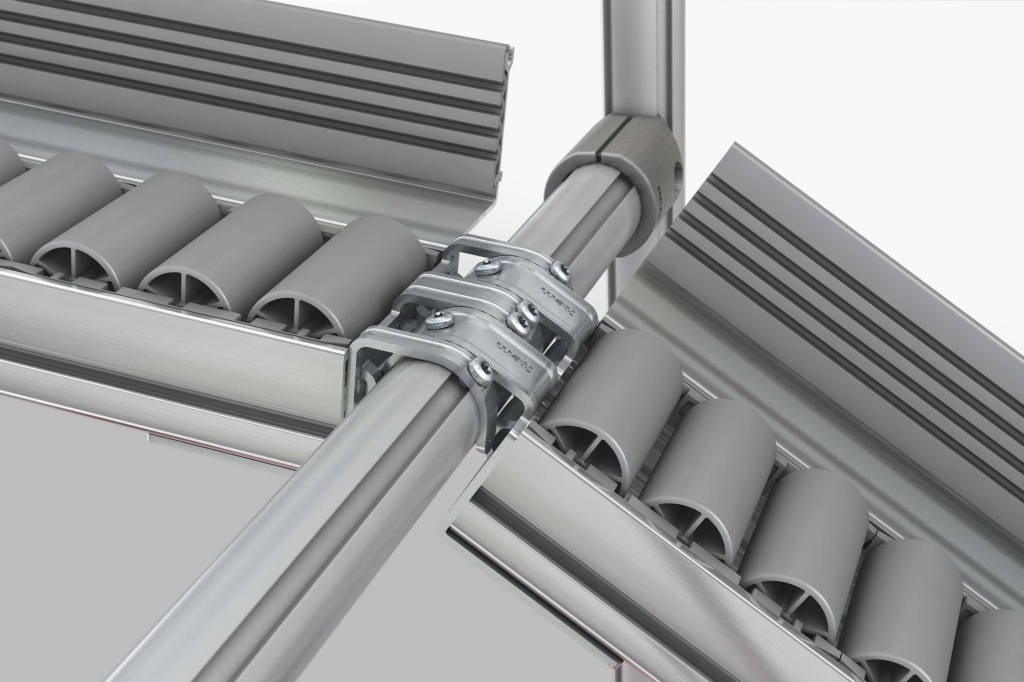

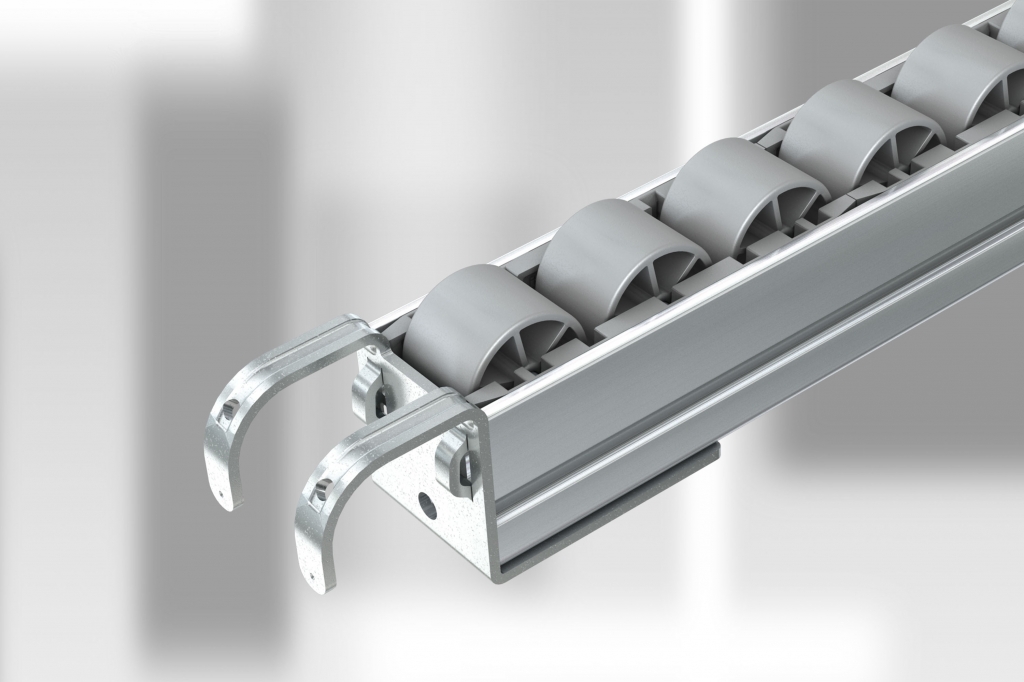

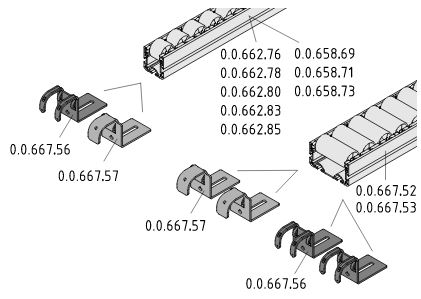

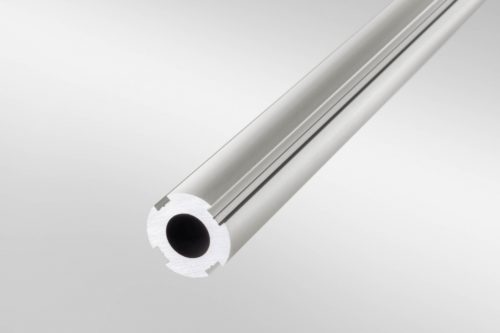

When two Roller Conveyors 6 with different gradients are to be connected together, Roller Conveyors 6 80×40 Al Fastening Bracket U D30 and I D30 are the solution. They hold the Castor Rails in place and together ensure that crates have a gentle and secure transition from one section to the next.

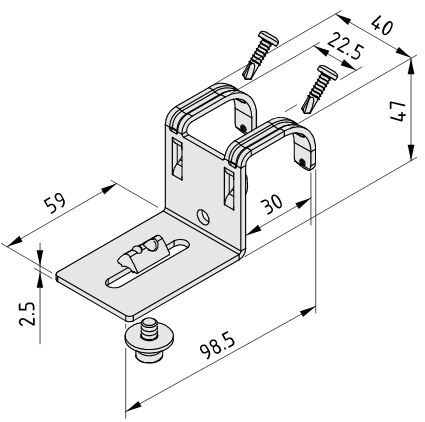

The brackets hold the Roller Conveyors 6 underneath with a screw and T-Slot Nut. Because the sides are left free, Guide Rails can now, for the first time on this solution, be fitted right up to the transition point. That makes the system even more reliable. The lack of large gaps means there is less chance that crates will get caught as they travel along the conveyor line.

Because they do not feature any side plates, Roller Conveyor Al 80×40 Fastening Bracket U D30 and Roller Conveyor Al 80×40 Fastening Bracket I D30 can be used for both versions of Roller Conveyor 6. In the case of Roller Conveyor 6 40×40 E D30, one bracket is fitted to each Roller Conveyor end, while two brackets are fitted to each end of the wider Roller Conveyor 6 80×40 E D30.

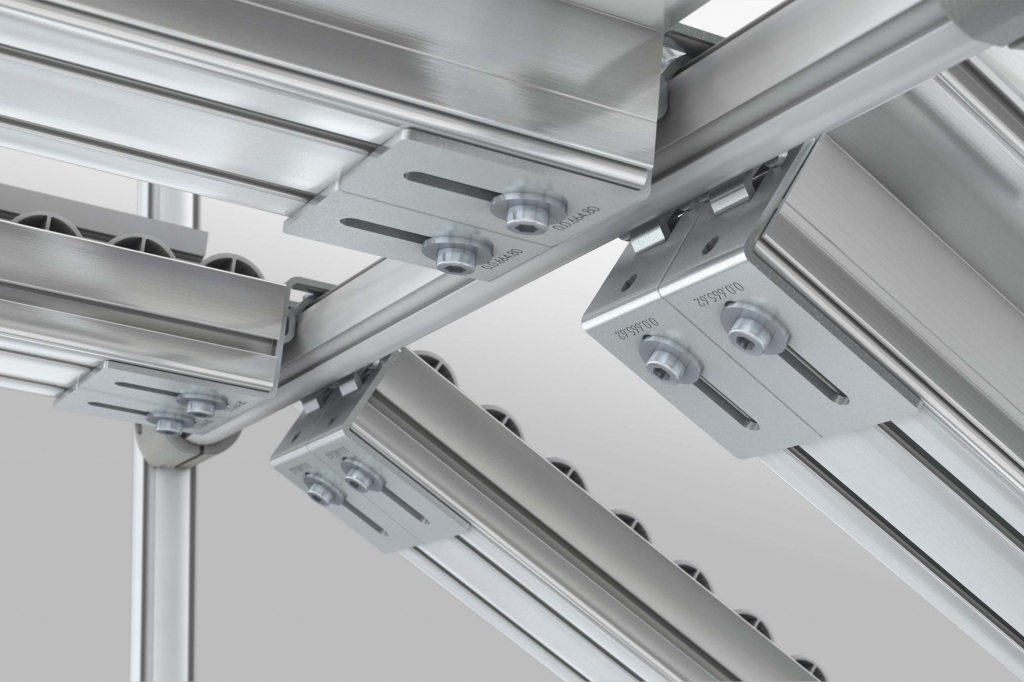

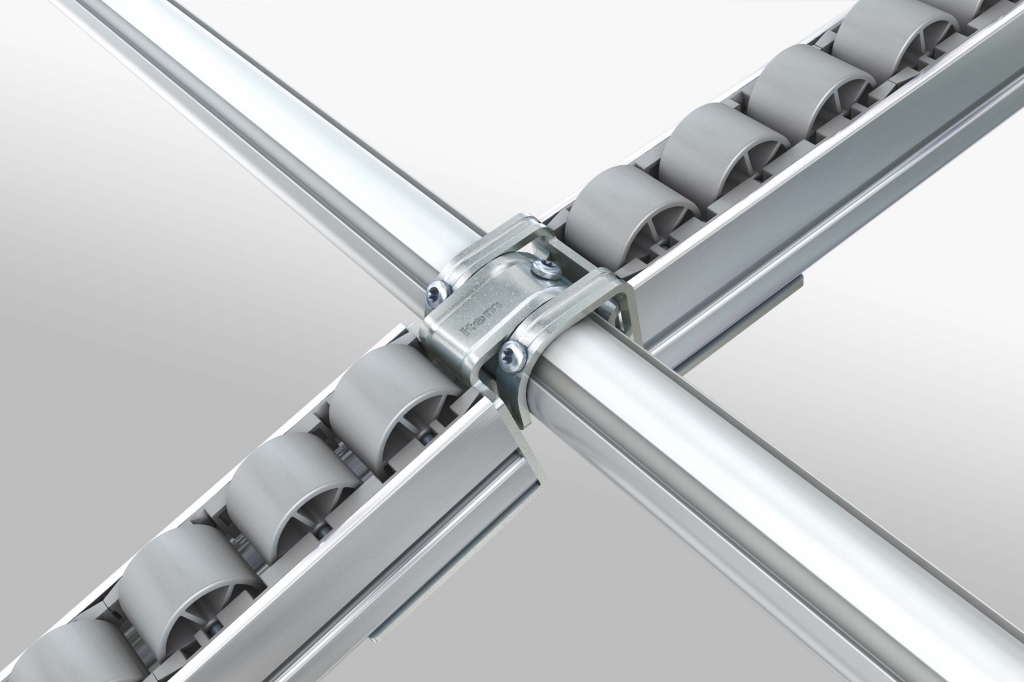

When connecting together two Roller Conveyors 6 Al that have different gradients, Roller Conveyor 6 Al Fastening Brackets U and I provide additional security. As the sides are left free, Guide Rails can be run right up to the transition point. The lack of large gaps means there is less chance that transport containers will get caught as they travel along the conveyor line.

Roller Conveyor 6 Al Fastening Brackets U and I hold the Castor Rails in place to ensure transport containers can pass smoothly and safely from one section to the next.

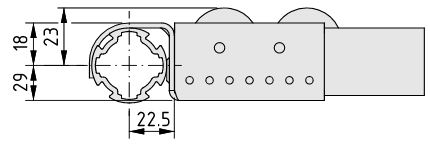

To achieve a stable connection, the Fastening Brackets connect to the underside of Roller Conveyors 6 Al with a screw and T-Slot Nut.

Because they do not feature any side plates, Roller Conveyor 6 Al Fastening Bracket U D30 and Roller Conveyor 6 Al Fastening Bracket I D30 can be used for both versions of Roller Conveyor 6. In the case of Roller Conveyor 6 40×40 E D30, one bracket is fitted to each Roller Conveyor end, while two brackets are fitted to each end of the wider Roller Conveyor 6 80×40 E D30.

- St, bright zinc-plated

- 2 Button-Head Screws self-tapping St 3.9×16, TX20, bright zinc-plated

- Hexagon Socket Head Cap Screw DIN 6912-M6x12, St, bright zinc-plated

- Washer DIN 9021-6.4, St, bright zinc-plated

- T-Slot Nut 6 St M6, bright zinc-plated